CONSTRUCTION & DEMOLITION

CONSTRUCTION & DEMOLITION

We provide custom solutions for the following areas:

- Bridge Maintenance & Repair

- Concrete Scarification & Restoration

- Hazardous Material Removal

- Hydro Excavation

- Roadway Stripe Removal

- Structure Restoration

- Tank & Pool Maintenance & Repair

BridgeMaintenance Repair

Removal of concrete in order to reinforce underlying steel rebar before re-pouring new concrete. Common materials include concrete, asphalt, paint and coatings, among others.

Benefits of Water

Conventional jackhammer tools damage and/or deform the rebar and surrounding structures. Water jetting, however, does not impact rebar integrity, but it does clean and remove rust from the rebar, which increases adhesion to the new concrete.

Recommended Equipment

Pump Systems:

20K psi @ 38 GPM for removing large concrete deposits

40K psi @ 8 GPM for removal of paint/coatings and rebar cleaning

Tool Systems:

Dump Guns

Rotary Guns

Triangle Shapejets

Accessories:

Flow Splitters

Diverter Valves

Concrete Scarifying & Restoration

Roughening or removal of the top layer of concrete (1/8") so that a new surface can be poured. Common materials include concrete, paint, and coatings, among others.

Benefits of Water

Water jetting provides faster production, versus conventional grinding machines, and is dust-free. Water jetting also provides a consistent surface finish that results in a stronger bond between the old surface and the new concrete.

Recommended Equipment

Pump Systems:

20K psi @ 17 GPM for larger surfaces

40K psi @ 8 GPM for precise, detailed work

Tool Systems:

Miniscrubber

Rotary Guns

Dynamo (manual, electric driven) and Vacuum

Accessories:

Diverter Valves

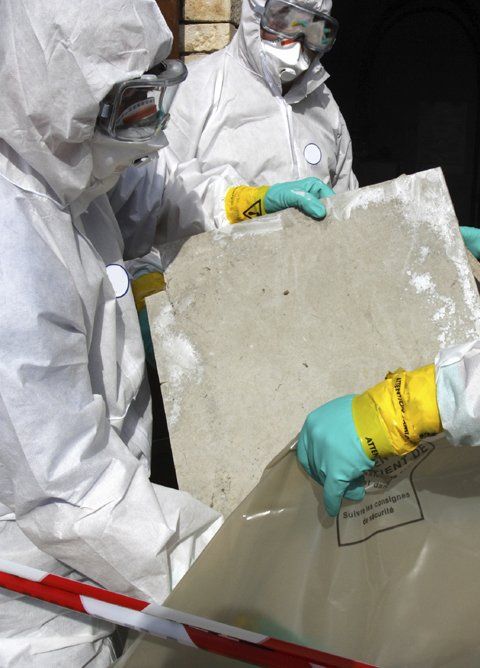

Hazardous Material Removal

Removal of coatings that contain hazardous materials, such as lead and asbestos. Common materials include lead paint (coatings) and asbestos, among others.

Benefits of Water

Conventional blasting creates hazardous dust particles that can be inhaled by operators. Water jetting instead wets the material, causing it to fall to the ground where it can be easily and quickly collected without becoming an airborne hazard.

Recommended Equipment

Pump Systems:

10K psi @ 33 GPM for soft material

20K psi @ 17 GPM

40K psi @ 8 GPM for hard material

Tool Systems:

Miniscrubber

Rotary Guns

Dynamo (manual, electric driven) and Vacuum

Dump Guns

Accessories:

Flow Splitters

Diverter Valves

Hydro Excavation

Digging and removal of ground material in landscaping, construction, and other excavation applications. Common materials include earth, rock, and concrete, among others.

Benefits of Water

Water jetting will not damage pipes and other utility lines, but will minimize damage to

the surrounding environment because it’s performed using manual tools that operators

can control with a level of precision that they cannot achieve using conventional excavation equipment (heavy machinery).

Recommended Equipment

Pump Systems:

5k @ 5-15 gpm for smaller projects or detailed work

10k @ 30-65 gpm for larger projects

Tool Systems:

Miniscrubber

Rotary Guns

Dynamo (manual, electric driven) and Vacuum

Dumbp

Dumbp

Accessories:

Flow Splitter

Diverter Valve

Roadway Stripe Removal

Removal of epoxy stripes and surface cleaning on roads and runways. Common materials include paint (coatings), tar and rubber buildup, among others.

Benefits of Water

Water jetting does virtually no damage to the underlying road or runways, whereas conventional grinders can remove up to ¼” of underlying road work. Water jetting is also dust-free and provides options for containment and collection of blast water and debris.

Recommended Equipment

Pump Systems:

40k @ 8 gpm

Tool Systems:

Miniscrubber

Rotary Guns

Dynamo (manual, electric driven) and Vacuum

Dump Guns

Accessories:

Flow Splitters

Diverter Valves